0300010

0300010

FIX N GO, 2 meter, "abrasive resistant" 5x10 and 5x12

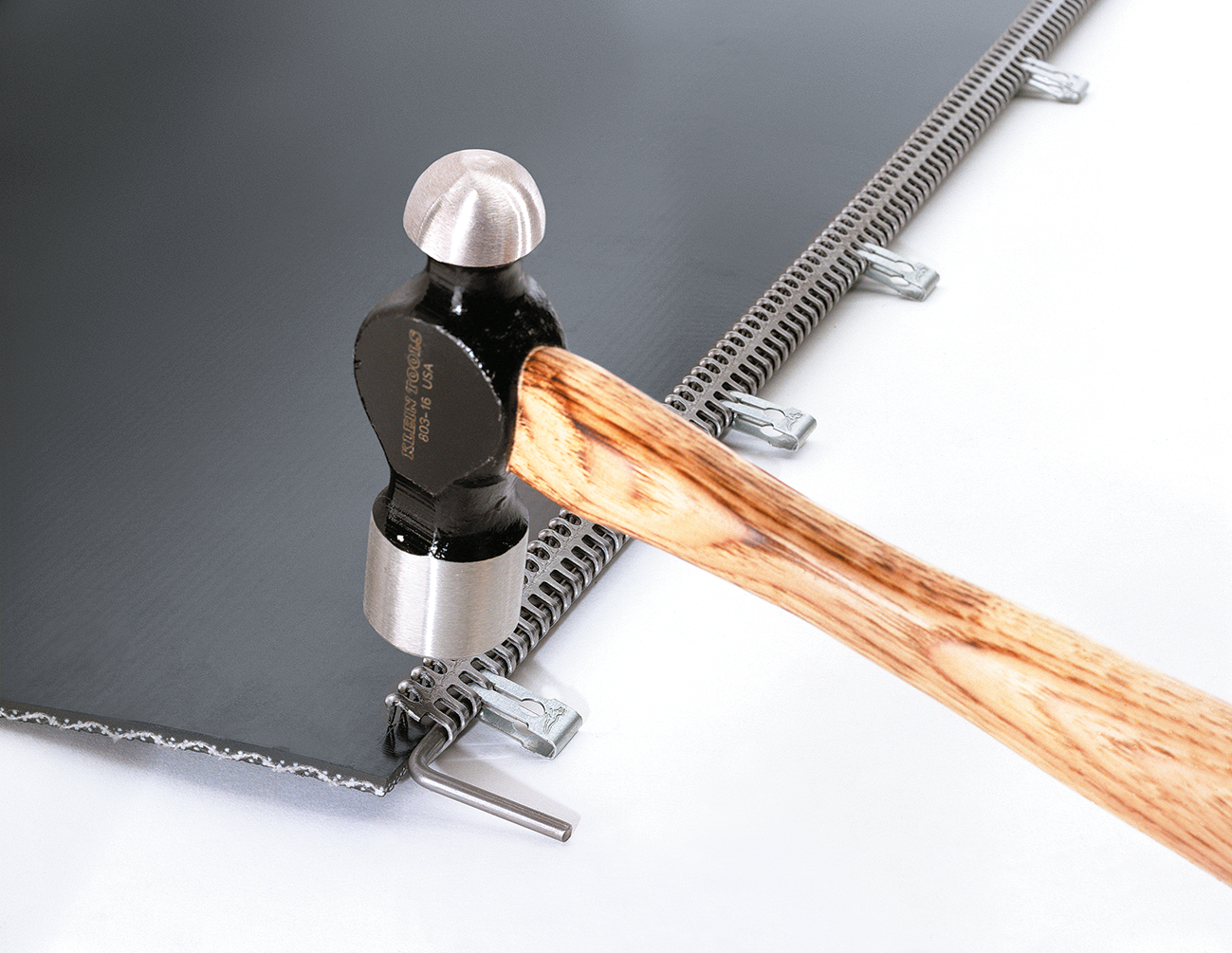

Fix’N Go® is an innovative and unique solution for repairing belt rips and tears.

Thanks to the 50 mm³ rubber used, FIX’N GO® has a higher abrasion resistance than most of your conveyor belts used without impacting its flexibility, resistance to elongation and tensile strength.

By repairing your belt with FIX’N GO®, you use a quick and long term permanent solution. No need to replace it.

MLT specific screws are self-drilling and self-tapping : they spread the carcass threads without cutting them.

Fix’N Go® can be used for repairing longitudinal rips, tears, holes and belt edge damage.

Fix’N GO® can also be used for splicing two belts together, in the longitudinal direction.

Fix’N Go® can be used for all textile carcass belts, up to 1250 N/mm.

Technical Characteristics

• For all textile carcass belt

• Tension up to 1250 N/mm.

• Anti-Abrasion and Heat Retardant

• Stainless steel or carbon steel inserts and screws

• Width : 158 mm

• Thickness top plate : 3 to 4 mm

• Thickness bottom plate : 2 to 3 mm

• Quantity of screws per meter : 150

Packaging

• Available in boxes of 2 meters or 20 meters, with screws.

Installation tools

• Battery, electric or pneumatic operated drill or screwdriver

• Belt skiver

Essential information from Leijenaar

Receive crucial information about the latest developments in Control handles, lubrication and conveyer components.

More than 2.500 product specialist preceded you.